By Lydia Hsu

Lydia Hsu is a Farmer Services Coordinator at Georgia Organics.

On a beautiful day in late September, Georgia Organics hosted the first of a series of Organic Growers Farmer Field Days. These educational workshops are specifically geared towards transitioning and Certified Organic farmers. The September workshop, “Raising Profits & Organic Livestock,” took place at Grateful Pastures Farm — the only Certified Organic poultry farm in Georgia — owned and operated by Shaun and Sabrina Terry.

Grateful Pastures Farm. Photos by Cait Carr Photo.

FARM TOUR

The workshop started off with an in-depth farm tour. Shaun walked attendees through the brooders, pens, and pastures, where participants were graced by a guest appearance from Flower, the youngest Terry child’s rogue pet chicken. The brooder at Grateful Pastures is an insulated shipping container that can hold up to 1,000 chicks and is where the chicks spend their first two to three weeks of life. Walking through the knee-high pasture, one can see the four pens that house the pastured poultry that are moved daily so the chickens get fresh pasture every day. Shaun designed and constructed the chicken pens, using design details resulting from trial-and-error and refinement of Grateful Pastures’ farm systems. The old pens that used to be moved by hand were smaller, and the feeders sat on the ground. The current chicken pens seen during the farm tour certainly did not look DIY; here’s a rundown of Shaun’s custom-engineered design:

Hands-Free Interior

Nothing inside the chicken pens needs to be moved by hand. Everything now hangs for ease of moving, including feeders and water.

Protection from Predators

Shaun uses hardware cloth, not the namesake ‘chicken wire’, to ensure each chicken pen is well-sealed and protected against intrusion by hawks, owls, raccoons, and other likely predators. A previous weasel issue revealed that the predator could squeeze through the 1-inch chicken wire hole!

Structural Framework

Standard 2x4 wood is being used for the pens’ structural framework, and steel is used for the ground beams. This allows Shaun to avoid wood rot and frequent replacement of pens.

Chicken Capacity

The old pens used to hold 130 chickens, but now hold up to 300! This improvement contributes to greater labor efficiency across the farm crew, cutting their daily chore time in half.

Automated Pen-Hauls

Moving the pens is a 1-person job now. Each pen is pulled from 3 points on steel ground beams, so they don’t bow out. Using the truck, Shaun attaches a cable that leads to a remote-controlled winch, and all he needs to do is go inside the pen and use a broom to keep the chickens off the back wall while the pen is being pulled.

Attendees gathered around during the stop on the farm tour at the chicken pens. Photos by Cait Carr Photo.

TO SELL OR NOT TO SELL.... EGGS

Grateful Pastures Farm has left behind raising laying hens in favor of solely growing their Cornish hens for meat. Sabrina and Shaun found that since the demand for eggs at the farmers market is so variable, it’s hard to maintain their profitability. Also, as livestock farmers, managing the opposing needs to keep their meat frozen and eggs refrigerated proved to be a stress point. Ultimately, the Terrys determined that the diverse infrastructure needs of selling eggs added a layer of extra logistics to their system, so they decided to cut it out.

That being said, vegetable farmers who are considering adding eggs to their operation could, in fact, utilize the same post-harvest storage infrastructure they use for other crops – something to consider if you’re a vegetable grower who wants to diversify your farm products!

PASTURE MANAGEMENT

When asked about their pasture management, Shaun replied that they like to minimize their interference with what nature intends for the land. For Grateful Pastures, that means not tilling or applying fertilizers. While they don’t currently plant in the pasture, Shaun is considering seeding legumes to increase the forage quality where the chickens have knocked back the pasture. The National Organic Program standard 205.239 requires poultry to have outdoor access but does not specify the square footage or pasture access. However, pasture access provides poultry with a varied diet, fresh air, and humane care that helps enhance their immune system to protect them from viruses and diseases, and also produces more nutritious chicken for the consumer.

Attendees saw firsthand the rich, biodiverse pastures during the farm tour. Photos by Cait Carr Photo.

EDUCATIONAL SESSION

The second half of the field day was an educational session with Shaun Terry and Patrick Dost, an Organic Inspection Manager from Quality Certification Services (QCS). As attendees settled into their seats under a shady pecan tree, Shaun and Sabrina spoke honestly about their experience as owner-operators of Georgia’s only Certified Organic poultry farm.

Why the Terrys Chose to Become Certified Organic

Considering policy makers only see two types of farming – conventional and Organic – Sabrina and Shaun want to demonstrate their support of organic ecosystems by being counted as Organic. Although Organic feed is expensive and calls for Grateful Pastures to sell their chicken at a higher price, carrying the Organic certification label helps them justify their prices to customers and buyers.

How They Source Feed

Shaun and Sabrina purchase their feed from Reedy Fork Organic Farm (North Carolina) and Kentucky Organic Farm and Feed. Reedy Fork is more expensive, but results in better chicken production, whereas Kentucky Organic Feed is less expensive but less optimal for production.

Also, consider how you’re going to get feed to your farm and how to store it. You’re going to need a lot of it, so buying in bulk makes the most sense. Feed mills can deliver with an auger and dump into a grain bin or deliver a tote sack, and you’ll either need a liftgate, forklift, or tractor with forklift.

Understanding Non-GMO and Organic Feed Labels

The Terrys noted that all Organic feed is non-GMO by default since GMOs are prohibited in Organic products (National Organic Program Policy Memo 11-13). The farmers also pointed out that feed labeled only as non-GMO may still be treated with substances that are prohibited in Organic production, like glyphosate.

Marketing and Sales with Organic Pricing

Shaun and Sabrina agreed that the key to making sales is to be transparent. They’ve discovered that while consumer education is a sales hurdle that’s necessary for any Organic farmer to overcome, once the customer understands why they’re paying more for Certified Organic chicken, they’re more likely to buy with confidence.

Grateful Pastures Farm has started taking online sales and has seen that orders are usually over $300, making virtual market stands a lucrative business and something to consider if you’re a farmer looking for options outside of selling at traditional farmers markets.

“People care about local Certified Organic pastured poultry. Find your audience and sell to that demographic. Charge what you need to charge, and don’t undersell yourself!”

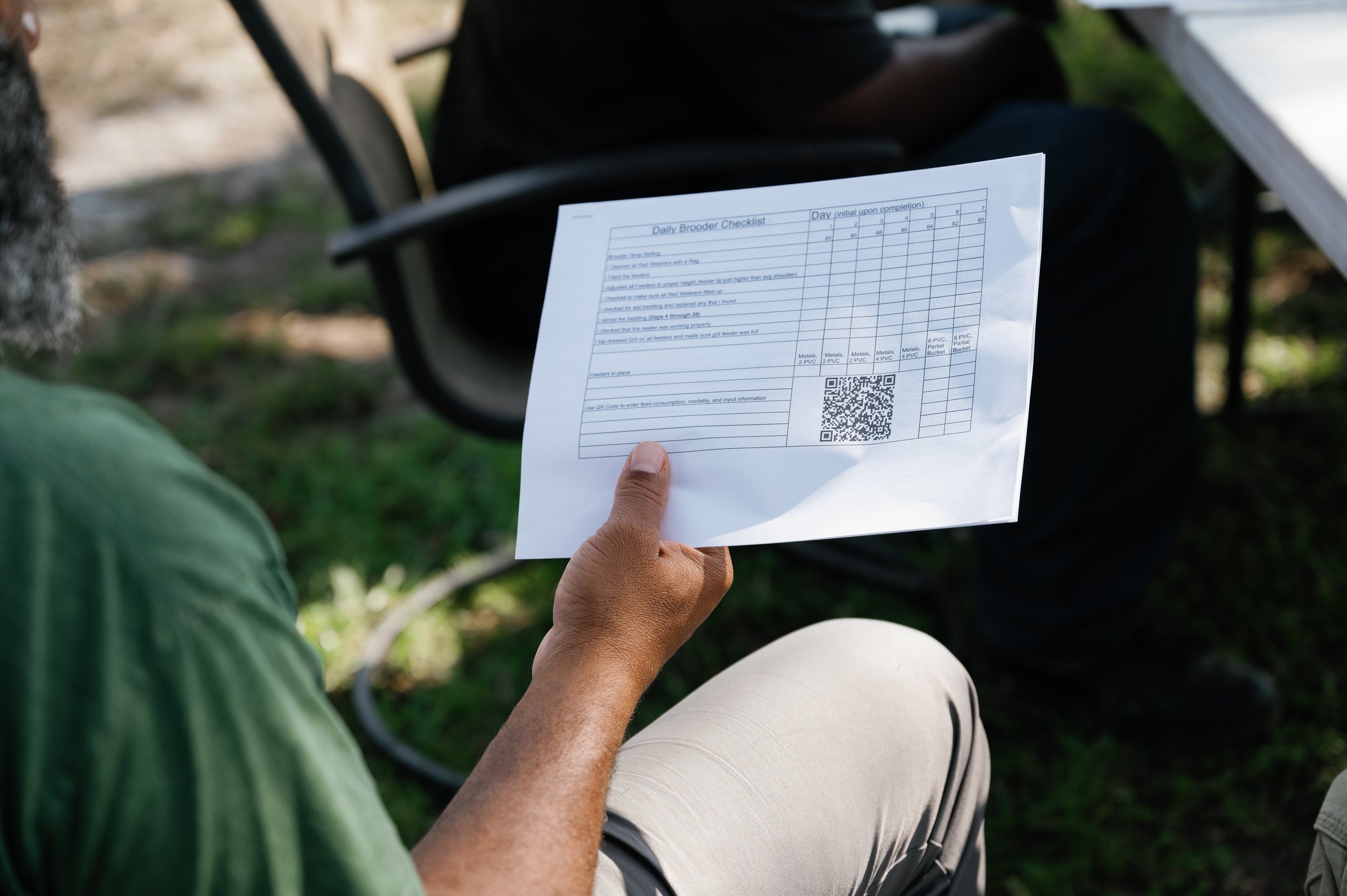

Grateful Pastures’ daily chore chart templates were passed around during the educational session so they could see the recordkeeping system that the farm created to fit their needs. Photos by Cait Carr Photo.

RECORD KEEPING AND ITS IMPORTANCE

A key topic that was touched on multiple times throughout the day was the importance of the recordkeeping required by the National Organic Program standard 205.103. As Shaun put it, even farmers who aren’t Certified Organic should still be keeping records. Keeping track of production factors such as feed purchased and consumed, mortality rate, and health care allow all farmers to make good business and farm management decisions. As Patrick Dost stated during his presentation on Organic ruminants and dairy, “Records maintain Organic integrity; records protect the farmer.”

So, how do you tackle the daunting task of building a recordkeeping system? Keep it simple. Take Grateful Pastures for example, they just keep a chore chart hanging in each chicken pen with a checklist for the crew member performing the daily chores to sign-off on. The chart includes a QR code that takes them straight to a Google Form so they can document feed consumption, mortalities, and/or other things of note. This way, the whole farm remains accountable, and the easily accessible data sheets help make recordkeeping a habit.

A beautiful lunch catered by Jenn Nylander of Good Foods Kitchen featured Grateful Pastures’ chicken. Photo by Cait Carr Photo.

After the workshop wrapped up, attendees were able to further connect over a shared meal catered by Jenn Nylander of Good Foods Kitchen . Grateful Pastures’ Certified Organic chicken paired with locally sourced seasonal vegetables highlighted our delicious meal and sent us on our way from the farm with a hearty knowledge that raising livestock Organically can raise profits.

WE’RE PROUD TO SERVE GEORGIA FARMERS

Thank you to Shaun and Sabrina Terry for hosting the Organic Growers Farmer Field Day at Grateful Pastures Farm, Patrick Dost from QCS for sharing your knowledge on ruminant and dairy certification, Caitlyn Bobo of Cait Carr Photo for capturing the beautiful day, and Jenn Nylander from Good Foods Kitchen for catering a delicious meal the attendees could all share together.

To learn more about Grateful Pastures Farm, visit www.gratefulpastures.com or follow them on Facebook (@gratefulpasturesfarm) and Instagram (@gratefulpastures).

To learn more about Georgia Organics visit georgiaorganics.org or follow us on Facebook, Instagram, Twitter, LinkedIn, and YouTube.

To view the resources passed out from the field day, click the button below. Please download the resources you would like to save by Nov. 30, 2023.

If you are a current or transitioning Certified Organic grower, check out the resources we have available for you through our GO Organic! Program.

To learn more about our Georgia Organics Farmer Services programming, check out our website.

Want to keep up to date on future farmer-focused events, farmer resources, updates, and news? Join our monthly e-newsletter, the Grower News, for all the latest!

This event was supported through the United States Department of Agriculture (USDA) Transition to Organic Partnership Program (TOPP). TOPP is a program of the USDA Organic Transition Initiative and is administered by the USDA Agricultural Marketing Service (AMS) National Organic Program (NOP).

This work was supported by the Beginning Farmer and Rancher Development program grant no. 2021-70033-35712/project accession no. 1027488 from the USDA National Institute of Food and Agriculture. Any opinions, findings, conclusions, or recommendations expressed at this event are those of the presenter(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.